DYNAMIC IMPROVEMENT GROUP

INC.

Engineered Inventory

We identified key inefficiencies: inflated demand from inefficient MRP settings, inconsistent production schedules, and personality-driven decisions rather than data. The lack of automated links between production schedules and supplier releases caused misalignment, while ineffective cycle counts led to negative inventory records. Shipping patterns and mixed-model production were suboptimized.

Order to Delivery Process Diagnostic

Formal Assessment

When clients seek inventory reduction, we conduct a comprehensive Order-to-Delivery Process Diagnostic, analyzing key areas like customer demand setup, inventory receiving, demand segmentation, and accuracy. We review production scheduling, shipping frequency, supplier releases, and shop floor performance to identify inefficiencies causing excess stock. By optimizing these processes, we reduce waste, improve flow, and cut carrying costs—freeing up working cash without sacrificing service, productivity or quality.

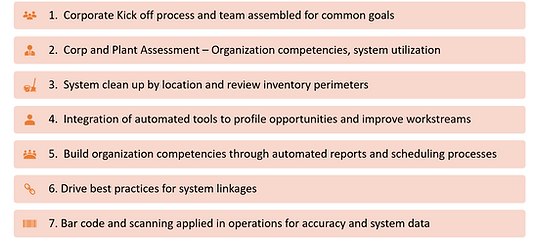

Structured Approach to Engineered Inventory

Our Engineered Inventory methodology applies a disciplined, structured approach to shift inventory management from reactive to strategic.

Demonstrated Benefits

Customer Names Redacted Per Privacy Agreement

Clients typically achieve multi-million-dollar inventory reductions—often 25-40%—while maintaining or even improving manufacturing uptime and service levels.