Improve your Systems Approach for Materials Management

- Ben Roush

- 21 minutes ago

- 3 min read

Unfortunately, a good fork truck driver does not make a very good scheduler. It requires a completely different set of skills, not just product identification and knowing what truck the shipment goes to.

The lost management art of Materials Management competencies is fleeting here in the US.

Getting your team to utilize your MRP system can save you tremendous cost, heart ache and turnover. It can be a fair amount of work as well. You will need a committed corporate materials sponsor, and good IT guys who will collaborate with you on setting the system up for Materials management competencies.

Post Covid turnover and attrition rates have ravaged the manufacturing sector with real losses, forcing people to go into their own excel spreadsheets that lack real time linkage and accuracy. I hate going into a building to watch the materials manager and her whole staff out on the shop floor looking for and counting parts and containers.

It does not really make any difference whether your business is in volume production or build to order profiles. The system’s approach is the way to go. It does not matter if its SAP, QAD, CMS or Oracle. You can with the right level of experienced resources get yourself back into the system and let it do its thing.

Why do we always find ourselves so far outside our own MRP system? Usually it is a competencies issue, and we lose our way between our corporate Materials and IT groups. Somebody or someone left, and we launched our last product line without filling in the BOMs, routings and perimeter settings.

No trust in the system drives everyone to internalize into their own worlds.

Typical perimeter set ups can get polluted over time with extra safety days, safety time, safety stock. Added lead times can exponentially drive you into boat loads of extra stock. After all – I do not want to be the one who runs us out of stock right?

MRP systems need to be accurate, cleaned up, responded to, and reinforced along the way.

After the system is set up, you can begin building some automated reports and really start to run the building for profitability. I think you would be shocked to find out how much time your materials group spend going from screen to screen to put together your reports, not to mention their own spreadsheets.

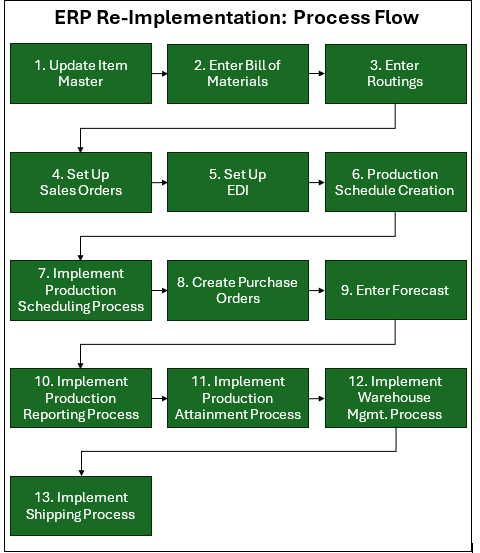

You can do this. You can pull your team together and make a commitment to get yourself back into the system and train your organization to use, manage and drive your staff to use what MRP system you have. You don’t need the next rev level. You don’t need a different system. This is what it looks like step by step:

Questions for you:

1. How far outside the system are you today?

2. How about your demand planning? If you customer releases are only 50% of what they are taking, are you making good adjustments and making good decisions?

3. What position in your organization can benefit from system integration?

4. Has the materials group defined what they need to work better in the MRP process?

5. Is your IT organization on board?

6. Where are your operations team breakdowns occurring for inventory accuracy?

7. How functional is your current bar coding applications for shipping, receiving, and reporting production?

The DIG group can help you find your way and get back into your MRP system. We call it Engineered Inventory and we want to work with you and your team to successfully integrate into your MRP world.

Give us a shout……………..

Comments